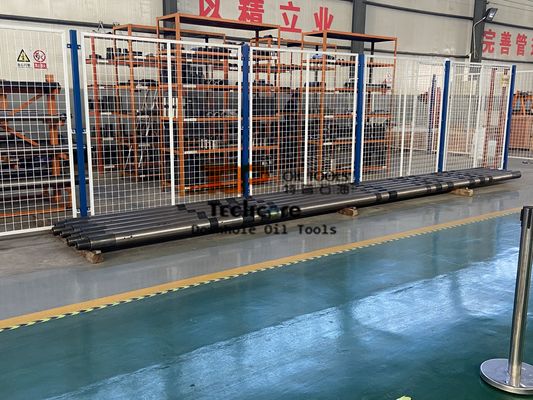

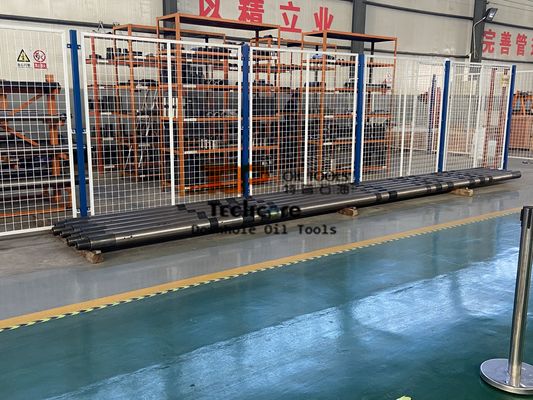

Downhole Tester Valve Working Pressure 15000 Psi For Well Testing Service

The downhole tester Valve is used for drill stem testing service. There are two types of downhole tester valve we supplied including select tester valve and LPR- N valve. The select tester valve is a full opening, annulus pressure operated tool used in cased holes. This tool has the capabilities of taking multiple downhole closures where pipe manipulation is restricted and a full opening string is desired

Structure of downhole tester valve - select tester valve

The select tester valve is composed of four basic sections; ball valve section, upper hydraulic section, nitrogen section and the metering section.

* The ball valve section contains the ball valve and the mechanism that rotates the ball when the tool is activated; the ball is rotated to the open

position allowing the reservoir to flow into the testing string.

* The upper hydraulic section is contained between the upper annulus ports and the nitrogen filler valve. The critical part of this section is the

metering (power) cartridge and selector.

* The nitrogen section is composed of the nitrogen case, nitrogen mandrel, floating piston and nitrogen filler valve. The nitrogen acts as an

adjustable spring and provides the force needed to close the ball valve.

* The metering section is composed of the lower oil chamber, metering cartridge and floating piston. The oil in this section acts as a barrier

between the tool and the annular fluid. This insures that only clean fluid passes through the metering cartridge

Technical parameter of downhole tester valve

| NO. |

Specification |

5” |

| 1 |

OD |

5”(127mm) |

| 2 |

ID |

2.25”(57mm) |

| 3 |

Length(mm) |

288.2”(7319.5mm) |

| 4 |

Working pressure |

15000 PSI(105Mpa) |

| 5 |

Maximum open pressure differential |

5000PSI(35Mpa) |

| 6 |

Internal Pressure Strength |

151Mpa |

| 7 |

External Pressure Strength |

141Mpa |

| 8 |

Torque strength |

30.9kN.m |

| 9 |

Service Environment |

Mud, crude oil, natural gas with H2S, Apply to NACE MR0175-2003 |

| 10 |

End connection |

3 7/8CAS. BXP, 3 1/2 IF BXP |

| 11 |

Service temperature |

-20oF~400oF |

Advantage

ZZ TOP Oil Tools Co., Ltd located in XI’AN City in China, is in full service on design, production and supply of oilfield downhole tools and Wellhead Equipment from 2010.In 2015 we rebuilt the factory for downhole tools to expand the R&D capacity and production capacity of drill stem testing tools and coiled tubing tools and establish the brand Techcore oil tools.

Now we have the professional Reserch and Development (R&D) department to improve the advanced technology in design of the Drill stem testing tools for well testing service. With more than Ten years development, our team is strong enough to design and choose the raw material of DST tools according to the customers' oil well condition. We always make all our effort to supply the cost effective well testing tools to satisfy the customer.

Our featured products includes following service:

* Drill stem testing tools (APR tools):

Full Bore Retrievable Packer, CHAMP Packer, HPHT Packer, RTTS Circulating Valve,

Rupture Disc Circulating Valve, RTTS Safety Joint, OMNI Valve, Multi-cycle Circulating valve, Downhole Tester Valve, Select Tester Valve, LPR N-Valve, Mechanical Tester Valve, Tubing Tester Valve, Super Safety Valve, BOP Safety Valve.

* Well Completion tools

Bridge Plug, Subsurface Safety Valve, Well Completion Packer

* Coiled Tubing Tools

Connector, Check Valve, Motor Head, Rotating Wash Tools, Surface Knuckle joint, Slip Slide Type Clamp, Centralizer.

* Perforating tools

Perforator, Perforating Gun System, Perforating Shaped Charge Case.

Welcome to contact us for more information!

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!